Structure and use conditions of PE separator

- By: JH Battery

- Sep 25,2023

follow us

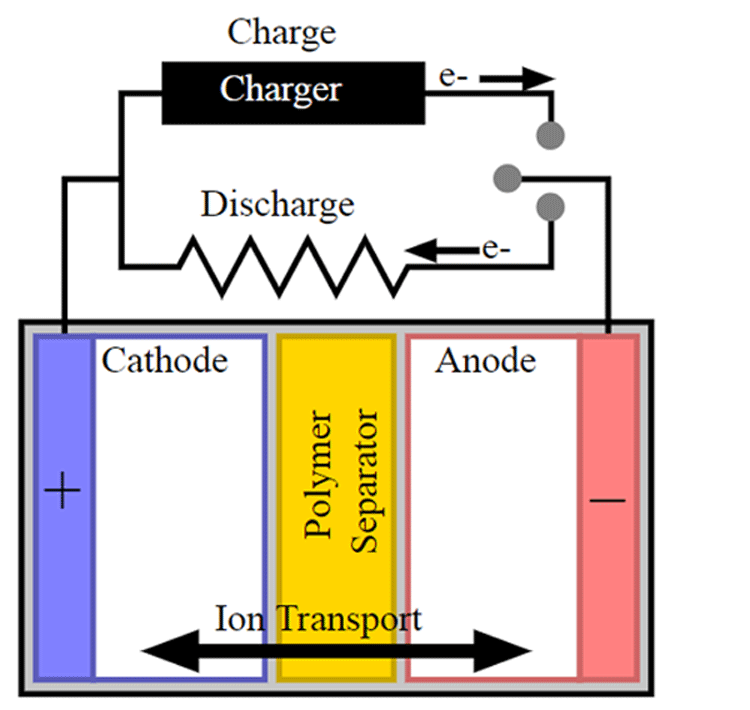

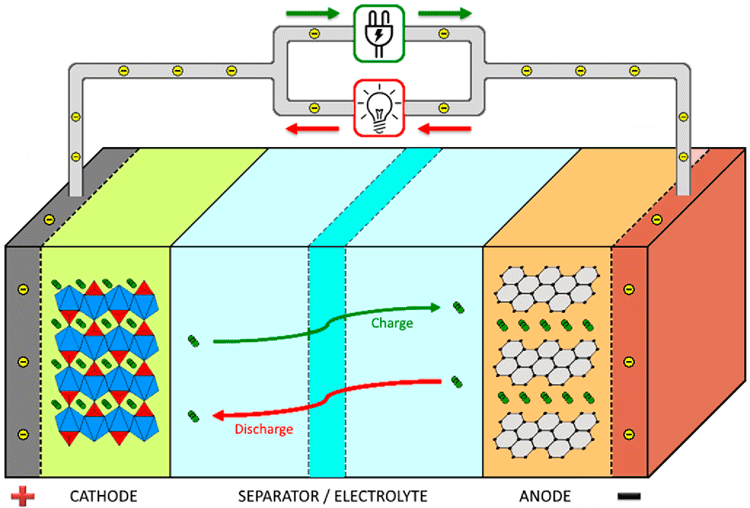

The function of the PE separator is to separate the positive and negative plates that rely on each other to prevent short circuits due to contact with each other. The PE separator material should have good acid resistance and oxidation resistance. Commonly used separators include wooden separators, microporous rubber separators, microporous plastic glass fibers and cardboard. PE separators usually have grooves on one side. When installed, the groove surface should face the positive plate and be perpendicular to the bottom, so as to facilitate the circulation of electrolyte, the sinking of shedding active materials and the escape of air bubbles. The PE separator has fewer impurities, good acid resistance, high mechanical strength and other conditions.

PE separators are electronic insulators, and their porosity makes them ionically conductive. The resistance of the PE separator is an important performance of the separator. It is determined by the thickness, porosity, and tortuosity of the separator, and has an important influence on the capacity and terminal voltage level of the high-rate discharge of the battery. The stability of the PE separator in sulfuric acid directly affects the life of the battery, the elasticity of the separator can delay the drop of the positive active material, and the size of the pore size of the separator affects the short-circuit degree of lead dendrites. The PE battery separator can also prevent the antimony ions dissolved from the alloy of the positive grid from migrating to the surface of the negative plate, thereby reducing the self-discharge of the battery.

The battery case is made of materials with acid resistance, good insulation and high mechanical strength such as hard rubber or plastic. It is a container for accommodating electrode plates, separators and electrolytes. The function of dilute sulfuric acid electrolyte is to conduct electricity between ions through electrochemical reaction in the conversion process of electrical energy and chemical energy, namely charging and discharging, and participate in the chemical reaction of the battery. The PE battery separator (search product, CLICK HERE ) can prevent the active material of the electrode plate from falling off and the deformation of the electrode plate in the valve-regulated lead-acid battery, and prolong the service life of the battery.

The amount of shrinkage of the PE separator is small after the injection of sulfuric acid, and it is also required that the separator is under a higher pressure state when designing the battery. The resistance of the PE separator and the resistance formed at the contact with the electrode plate are part of the internal resistance of the battery, which requires the separator itself to have a low resistivity, and also requires the battery to be designed so that the separator is under a high pressure state, so that The PE separator is in close contact with the electrode plate to reduce the resistance formed at the contact. The PE separator material itself is an insulator, and the battery separator must have a loose porous structure.

--End--

English

English Russian

Russian Portuguese

Portuguese Arabic

Arabic Bangla

Bangla Indonesian

Indonesian