What you must know about AGM separator

- By: JinHan

- Oct 23,2023

follow us

For flooded batteries, the basic function of micro-porous separator is to isolate the plates with opposite polarity, avoid electrical contact between them, and ensure high ionic conductivity at the same time, allowing ions to move freely between the plates.

The AGM separator used by VRLAB has the following additional features:

- Absorb the electrolyte (the third active substance of the battery) so that it does not flow. Provide relatively large gas transmission holes for oxygen diffusion, and thus promote the operation of COC.

- Guarantees high ionic conductivity. Provide a transport channel for the ion flow, enabling it to be transported between the two types of plates, allowing the redox reaction to proceed rapidly.

- Limit the volume expansion of PAM, maintain the polar group pressure, and minimize the pulsation effect of positive active substances during circulation.

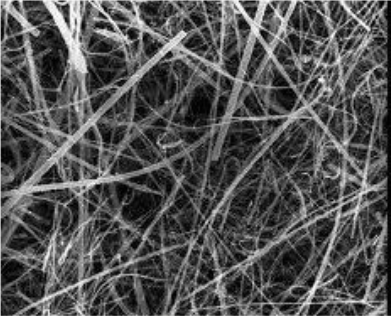

Figure 1 shows the scanning electron micro-graph (SEM) of the AGM diaphragm sample.

It can be seen from the figure that the AGM diaphragm is composed of chemical grade borosilicate glass fibers, which are 1~2mm in length and different in thickness (diameter: 0.1~10 μ m). The proportion of different fibers determines the balance between different functions of the diaphragm and the price of the diaphragm. These fibers are hydrophilic and absorb electrolyte. The surface area of the finer fibers (i.e. fibers with smaller diameters) in the separator is larger, and the inner diameter of the pores formed is smaller, but the price is higher.

(Figure 1)

(Figure 1)

AGM separators also contain 15~18% of PP, PE and other polymer fibers, which improve the mechanical strength of diaphragms, promote the formation of gas channels (because these materials are partially hydrophobic), and also reduce the price of diaphragms. The production process of AGM diaphragm is similar to that of paper-making, which makes it an an-isotropic structure. Its structural feature is that the aperture of the X-Y plane of the diaphragm is 2~4 μ m. The size of micro-pores perpendicular to the X-Y plane is 10~30 μ m[27]。 The function of the X-Y plane small hole is to make the electrolyte distribute in the thickness direction of the diaphragm, and maintain its wicking rate when the diaphragm is partially filled with electrolyte. Large pores form open gas channels.

Gas transmission through AGM separator:

After oxygen is separated from the positive plate, it is transferred to the negative plate, and then a reduction reaction occurs on the negative plate. The whole oxygen transmission process goes through the following stages.

First, oxygen forms tiny bubbles in PAM micro-pores filled with electrolyte. Then, these tiny bubbles gradually merge into discrete bubbles, which gradually replace the electrolyte in the plate micro-pores facing the separator. A small part of the oxygen in the bubbles reaching the surface of the electrode plate is dissolved in the electrolyte, while most of the gaseous oxygen is still at the interface of the electrode plate / separator in the form of bubbles. The AGM separator is a non-uniform structure, so oxygen accumulates in the parts with low fiber density (loose structure) on the AGM surface or in some vacant parts between the electrode plate and the separator (tubular electrode / AGM).

Applying pressure to the electrode group can make the contact between the glass fiber surface and the electrode plate surface closer, and promote oxygen to penetrate the diaphragm. There are two possible reaction mechanisms:

1 When the pressure of the pole group is low, the volume of gas accumulated at the interface of the pole plate /agm diaphragm increases. Under the action of gravity, the air flow will rise vertically. The density of electrolyte is twice as high as that of gas, pushing the gas upward into the upper space of the pole group. In this way, oxygen will leave the polar group. The vertical flow rate of gas depends on the current passing through the battery, the temperature of electrolyte and the service state of the battery (such as new battery or long-term battery).

2 When the pressure of the pole group is high, the diaphragm tightly presses the pole plate, and the bubbles enter the diaphragm. The bubble moves horizontally, trying to increase the gas channel in the diaphragm. The density of glass fiber material structure is uneven, and bubbles enter the parts with low fiber density. The bubble moves not only randomly, but also in parallel along the diaphragm surface, and in a direction perpendicular to the diaphragm surface. However, the gas flow mainly moves through the AGM diaphragm to the negative plate with the lowest gas pressure, and the pressure gradient pushes the oxygen to move in this direction. Under pressure, the gas replaces the electrolyte in the micropore of the diaphragm, and thus forms a gas channel. When a continuous gas channel is formed, the movement of oxygen between the positive plate and the negative plate is accelerated.

During the production of AGM separator used in VRLA battery, the thickness of separator is measured under the standard pressure of 10KPA. In order to improve the contact between the electrode plate and the separator, the electrode group (active body) is compressed, reducing the thickness of the separator by about 25%. Before installing the pole group of the high type fixed battery into the battery slot, tie it tightly with a plastic bandage to maintain the pressure of the pole group.

In conclusion, AGM separators are endowed with more functions, which are crucial for AGM batteries, no less than positive and negative plates. The pole group maintains a certain pressure, in addition to realizing oxygen transmission, it is more important to ensure the conductivity of the separator. (Search product, CLICK HERE)

--End--

English

English Russian

Russian Portuguese

Portuguese Arabic

Arabic Bangla

Bangla Indonesian

Indonesian